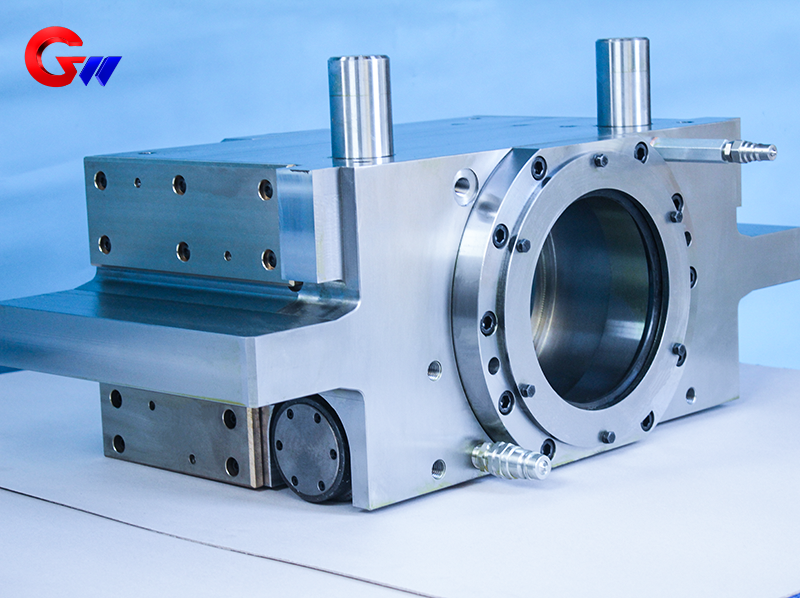

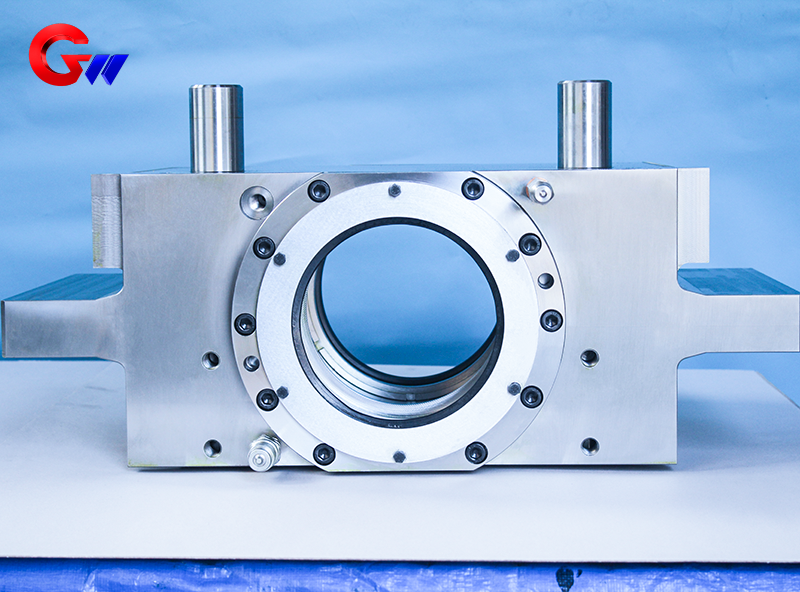

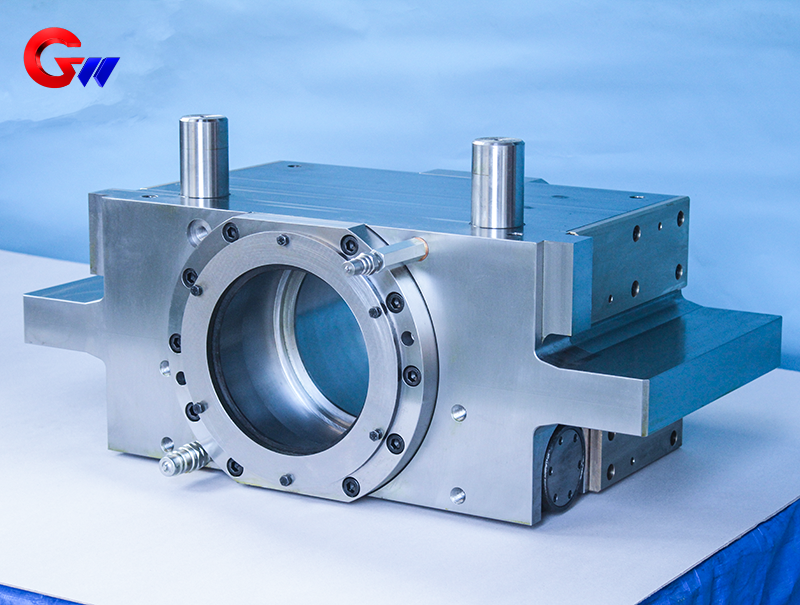

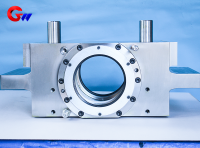

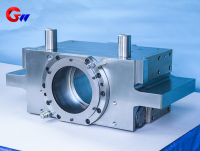

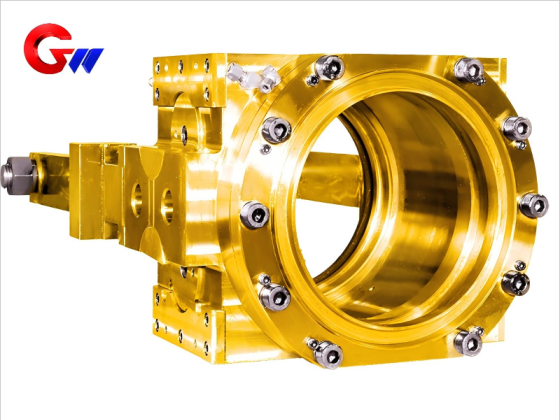

Cale de roulement à rouleaux intermédiaires pour machine de laminage à chaud

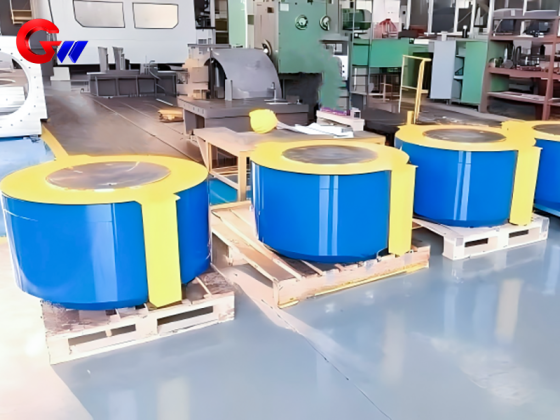

Avantages de la cale de roulement à rouleaux intermédiaires de précision GW :

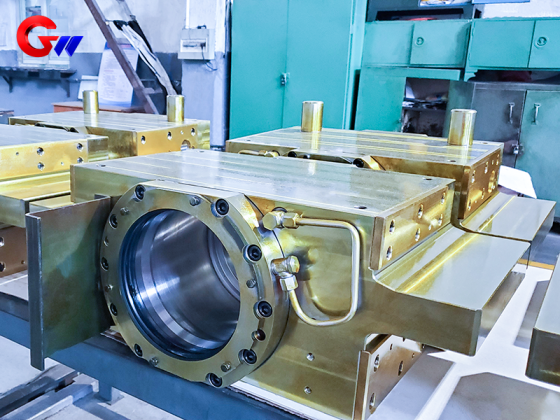

Équipement de fabrication CNC intelligent de haute précision, personnel de haute technologie, système de traitement mature, processus d'inspection de qualité strict, excellent processus de gestion de la production, est la garantie de produits de haute qualité.

Afin de mieux garantir la qualité des produits de cales de roulements à rouleaux intermédiaires, en plus de l'inspection régulière des dimensions, la société a acheté une machine de mesure standard à trois positions de type pont mobile de haute précision, la précision de détection jusqu'à 2 microns, pour assurer la base d'inspection absolue de diverses tailles de pièces et l'inspection des tolérances de comportement.

- Guangwei Precision

- Luoyang, Chine

- Stipulation contractuelle

- La capacité annuelle de la bobine d'acier est de 4000 pièces

- information

Intermediate Roller Bearing Chock Of Hot Mill Machine

The intermediate roll bearing chock in the hot rolling mill is a key component in the hot rolling production line, mainly used to support and fix the intermediate roll, withstand huge rolling force, impact force, and high temperature environment.

Application scenarios of intermediate roller bearing seat in hot rolling mill

work environment

High temperature: During the hot rolling process, the temperature of the rolling mill can reach over 800 ℃, and the bearing seat needs to withstand radiation heat and conduction heat.

High load: capable of withstanding rolling forces (up to thousands of tons) and frequent impact loads.

Dusty/humid: Rolling cooling water and iron oxide scale are prone to invasion, requiring high sealing and corrosion resistance.

Functional requirements

Accurate positioning: Ensure the parallelism and rolling accuracy of the rolling mill rolls.

Wear resistant and fatigue resistant: prolongs service life and reduces downtime maintenance.

Lubrication guarantee: A high-pressure lubrication system (such as oil air lubrication) is required to reduce friction and wear.

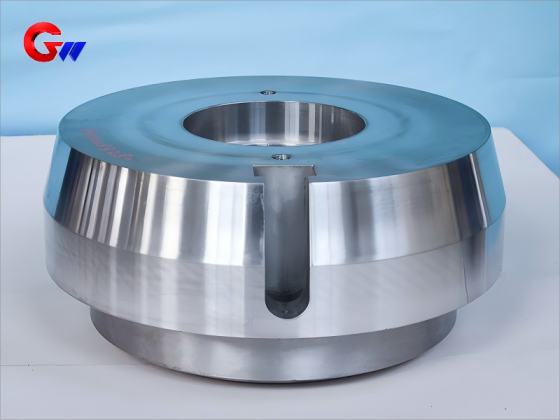

Heat treatment process of intermediate roller bearing seat in hot rolling mill

Heat treatment is a key step in improving the mechanical performance of intermediate roller bearing seats, usually including the following steps:

Pre treatment (normalizing or annealing)

Eliminate internal stress in forgings or castings, refine grain size, and prepare for subsequent processing.

Quenching+tempering (quenching and tempering treatment)

Quenching: Heating to a critical temperature (such as 850-900 ℃) and then rapidly cooling (water quenching or oil quenching) to obtain a high hardness martensitic structure.

Tempering: Medium temperature tempering (400-600 ℃) is used to balance hardness and toughness, avoiding brittle fracture.

Surface strengthening (optional)

Induction hardening: Local hardening of the bearing contact surface to improve wear resistance.

Carburizing/nitriding: suitable for high alloy steel, enhancing surface hardness and fatigue resistance.

Stress relief annealing

After precision machining, low-temperature annealing (200-300 ℃) is carried out to eliminate machining stress.

GW Precision manufacture all kinds of Intermediate Roll Bearing Chock and other mill precision parts.

GW precision intermediate roller bearing seat advantages:

high-precision intelligent CNC manufacturing equipment, high-tech staff, mature processing system, strict quality inspection process, excellent production management process, is the guarantee of high-quality products.